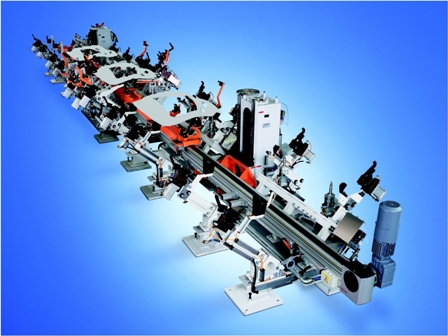

EXPERT-TÜNKERS monorail lift shuttle systems

The EXPERT-TÜNKERS monorail lift shuttle systems were developed on the basis of expansive studies in accordance with the criteria of market requirements.

Gneral information

The EXPERT-TÜNKERS monorail lift shuttle systems were developed on the basis of expansive studies in accordance with the criteria of market requirements.

• 3D-volume model in CATIA V5 for Simultaneous Engineering (SE) projects for early and efficient integration into the plant layout

• High degree of availability due to approved EXPERT-TÜNKERS technology

• Optimal transporting times

• Next to maintenance-free

• Standardised and optimal construction elements

• Economically efficient solutions

Transporting principle

EXPERT-TÜNKERS monorail lift shuttle systems transport several components synchronically, harmonically and shock-free from station to station. The components are lifted off synchronically, transferred horizontally and precisely deposited again at the next station. The gentle component transfer is carried out at V = 0 m/min.

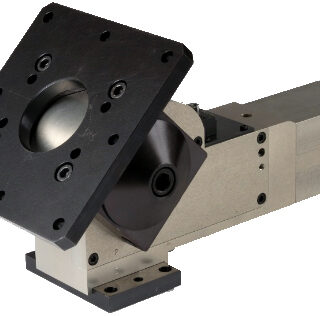

Monorail shuttle

Vertical drive

The vertical drive of the monorail lift shuttle system is based on two EXPERT-TÜNKERS standard lifters.

Advantages of EXPERT-TÜNKERS standard lifters:

• Approved drive concept of cylindrical cams and cam followers

• Harmonious and shock-free drive motion

• Gentle component transfer at V = 0 m/min

• Acceleration and deceleration pursuant to optimised laws of motion in accordance with the VDI guideline No. 2143

• Low input power

• Most precise, form-closed, mechanically locked end positions

Horizontal drive

The horizontal drive is based on an electromechanic standard linear axis.

Technical advantages of the linear axis:

• Freely selectable step lengths, i.e. flexibility

• Driven via a geared servo motor, i.e. flexible transporting speed

• Spaciously dimensioned aluminium profile with high flexural strength

• Robust roller guidance on integrated, shock-free steel rails

• Low-maintenance due to sealed-for-life rollers

• Weld-resistant cover of the drive belt

Technical data

Number of stations: 3 to 10 stations as a standard

Overall length: max. 20,000 mm

Horizontal travel: freely selectable

Travel time of horizontal travel: for example 2,500 mm in 2.0 sec

Vertical travel: min. 250 mm, max. 1,300 mm

Travel time of vertical travel: 600 mm in 2.0 sec

Height: 500 mm from floor level to top edge of acceptor

(The calculation of the movement speeds is subject to the travel length/customer load.)

References

• Audi Ingolstadt (Germany)

• Audi Changchun (China)

• Audi San José Chiapa (Mexico)

• Seat Martorell (Spain)

• Volkswagen Taubaté (Brazil)

• Volkswagen Anchieta (Brazil)