KE CDK-BAYO KIKK-EL SET

Tip Dresser/Changer Combinationautomatiserar tipshanteringen

CDK-BAYO KIKK-EL SET kombinerar formerare och elektrodbytare i en enhet. Det förenar våra två mest pålitliga och mest använda produkter, CDK-BAYO och KIKK-EL, och tar därmed automatiseringen i produktionscellen till en ny nivå.

På grund av de material som används har CDK-BAYO-formeraren en mycket lång livslängd och är idealisk för användning i alla produktionsmiljöer. Den kan användas i alla arbetspositioner. Det spelar ingen roll om det är horisontellt, vertikalt eller till och med upprätt. Den integrerade fjäderenheten säkerställer samtidig borttagning under elektrodfräsning.

Tip Dresser/Changer Combination – automates tip handling

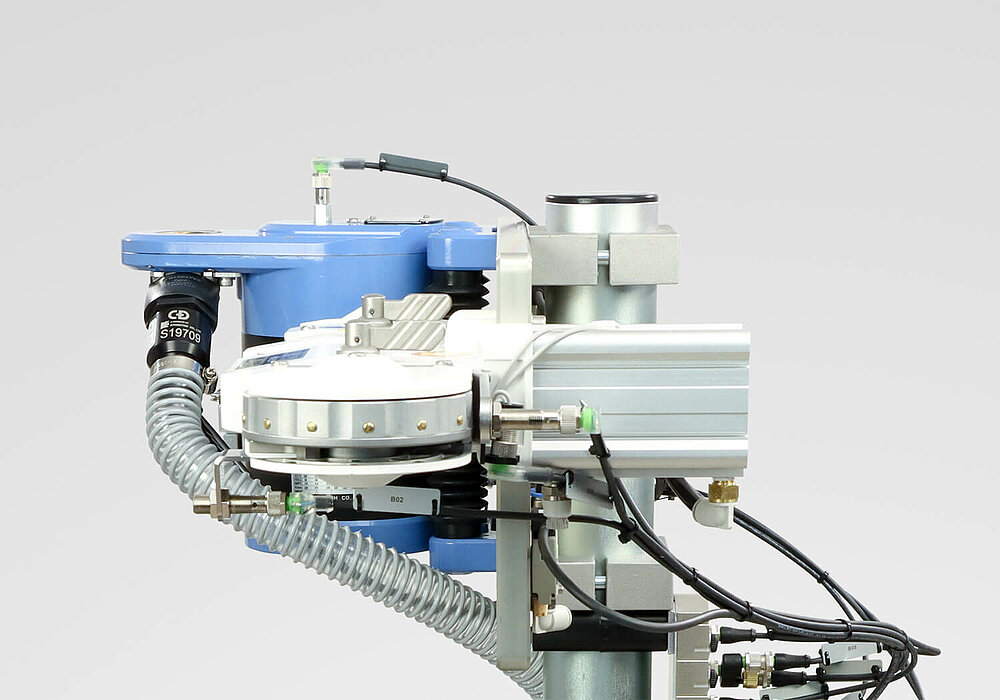

The CDK-BAYO KIKK-EL SET combines electrode tip dresser and tip change in one unit. It unites our two most reliable and widely used products, CDK-BAYO and KIKK-EL, and thus takes automation in the production cell to a new level.

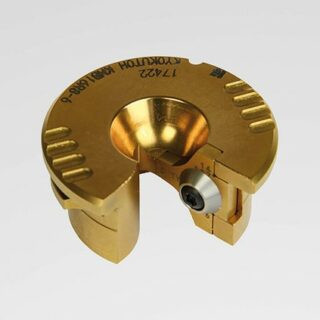

Due to the materials used, the CDK-BAYO tip dresser has a very long service life and is ideally suited for use in any production environment. It can be used in any working position. It does not matter whether it is horizontal, vertical or even upright. The integrated spring assembly ensures simultaneous removal during electrode milling.

Thanks to its pneumatic drive, the KIKK-EL tip dresser applies an enormous amount of force when loosening the electrode tips. This force is triggered by the integrated lifting unit in the linking device. This enables the tip changer to loosen electrode tips that are exposed to enormous forces during welding, of course also in the future-oriented field of aluminium welding. The KIKK-EL can also be used “as easy as pie” as a mobile version on the gripper for stationary weld guns. Due to the pneumatic mode of operation, no additional power connections are required, which would usually complicate such an installation.

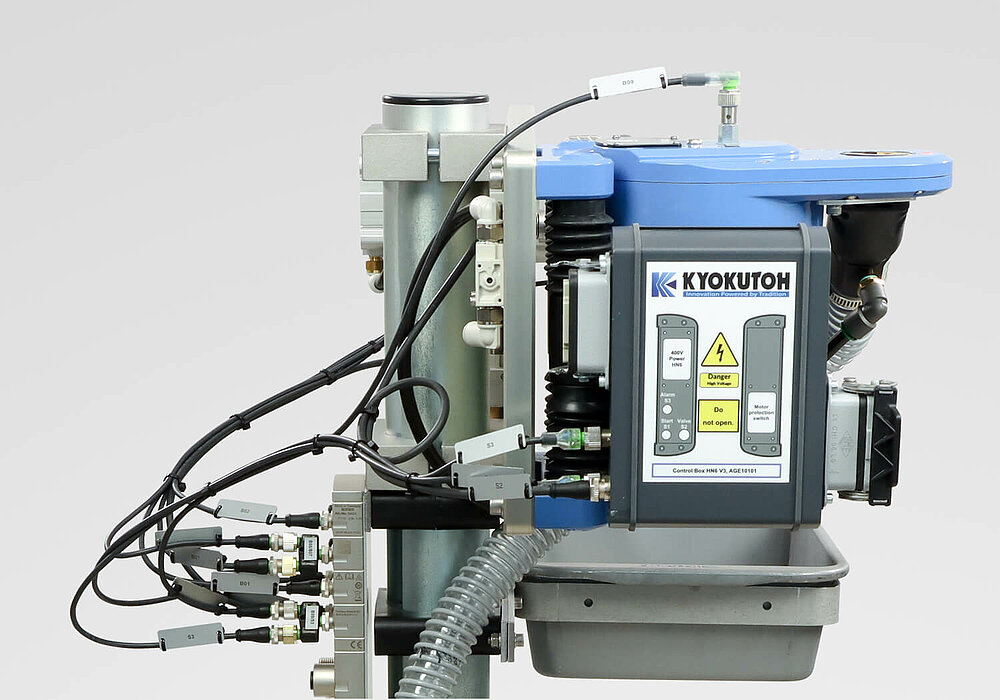

With the control box already integrated ex works, the system is easy and PLUG&PLAY to put into operation. The powerful chip extraction unit ensures that the chips are safely removed. An integrated motor protection switch is provided for the prescribed safety.

Advantages

- Dresser-changer combination automates tip handling

- Both units on a low-vibration and stable stand

- PLUG&PLAY system for simple and fast installation

- Bayonet fastened cutter holders

- Chip Vacuum System CVC5

- Integrated control box

- Simple and quick change of magazines

Technical Data

Specifications

Tip Dresser KE CDK-BAYO

| Voltage | 400V |

| Frequency | 50/60 Hz |

| Current | 2.3/2.2 A |

| Speed | 234/280 rpm |

| Weight | 14.5 kg |

Tip Changer KE KIKK-EL

| Tip lenghts | 18-25 mm |

| Tip diameter | 13, 16 and 20 mm |

| Air source pressure | 4-6 bar |

| Weight | 11 kg |