Robot welding cells

Vi erbjuder kompletta lösningar för robotsvetsning från en enda källa – från definitionen av svetsparametrar och processplanering genom utveckling och design och inklusive tillverkning, installation och idrifttagning. För att uppnå detta arbetar experter i vårt team från olika tekniska avdelningar hand i hand. Utvecklare och konstruktörer, tekniker och montörer. Steg för steg dyker din individuellt designade robotcell upp. Vi håller kontakten med dina specialister under hela processen för att se till att vi exakt förstår dina krav och kan implementera dem perfekt. Även om parametrarna råkar förändras under utvecklings- eller designfasen hittar vi en lösning tillsammans med dig. När allt kommer runt är din framgång vårt mål.

Ta fart med de automatiserade robotsvetsanläggningarna från NIMAK

Welding robots that will convince you: NIMAK welding cells

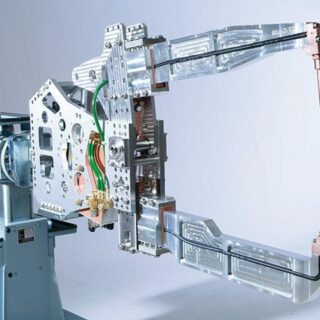

Nowadays, welding robots are used in nearly all production processes in industry. No wonder, considering the enormous need for flexible automation processes. Modern articulated arm robots convince in this environment with their great variability: They can be used in many areas – including welding cells that automatically execute entire manufacturing processes. We develop, design and fabricate such complete robot welding cells for you. Adapted exactly to your requirements and based on our welding expertise and many years of experience with robot technology. Let’s talk about your concrete welding challenges: We will make robot welding cells with which you can produce even more precisely and efficiently. Do you prefer a certain robot manufacturer? No problem! We are familiar with all renowned products. And if you don’t happen to have any special requirements, we will recommend the most appropriate one.

Standard robot cell or special solution – we provide both

The perfect robot cell is the one that best fits your needs. That is why we never reply to our customer inquiries with a reference to our product range; rather first we find out: Exactly what should the new welding plant achieve? What challenges does the robot welding need to master? Based on your answers we can then get together and start the development phase. During that, we constantly also consider whether one of our previously developed solutions could partially or completely meet your requirements. If yes, that results in time and cost advantages. We then build on existing standards and design your robot cell through specific adaptations and supplements. And if none of the existing solutions fit? For us, that is an incentive to develop and fabricate for you the optimum robot welding plant with welding robots, welding guns and everything that involves from the ground up.

Full service – for your resistance welding plant

We provide complete solutions for robot welding from one, single source – from the definition of the welding parameters and process planning through the development and design and including the manufacture, installation and commissioning. To accomplish that, experts in our team from various technical departments work hand in hand. Developers and design engineers, technicians and fitters. Step by step your individually designed robot cell emerges. We keep in touch with your specialists during the entire process to make sure we exactly understand your requirements and can implement them perfectly. Even if the parameters happen to change during the development or design phase we will find a solution together with you. After all, your success is our goal.

Take off with the automated robot welding plants from NIMAK

Our customer processed shelves for a high-bay warehouse in various sizes and wanted an automated solution: for more efficiency, precise welding and higher quantities. We developed a two-station welding robot plant for them that perfectly meets these requirements.

Pamphlet / Broschyr

Video

Challange

A prime example from real life:

Joining many workpieces of different sizes

According to the customer requirement, a welding plant needed to be developed that could completely automatically process variously sized shelves and simultaneously facilitate the ability for manual insertion using manipulators. The special challenges in this project also included, along with the great variety of more than 21 main and many sub-product variants that needed to be processed, the ability to weld material combinations of up to 6.5 mm.

Solution

A highly flexible two-station welding plant

To be able to automatically weld materials in the demanded different sizes and thicknesses, we have developed a highly-flexible two-station robot welding plant for components sized from 600 x 1,200 mm to 1,200 x 4,500 mm. It is equipped with a simple, fast tool conversion system and C-welding guns with 700 mm width that are designed for a sheet combination of up to 6.5 mm.

Results

Higher availability, faster processes, perfect welding quality

- Increased plant availability and shortened cycle times: Two-station plant

- Time savings in the production sequence While a robot is welding at one station, the next component can already be inserted and prepared at the second station.

- Easy to operate: Predefined position and snap-in points along with a component selection based on up to 800 preprogrammed variants

- Uniform and perfect welding quality guaranteed: Selecting a program that does not fit the component is already excluded during the population process. Position sensors in the tool can be combined and PLC queries can be run.

- Everything from one, single source Complete welding robot systems from the basic concept to commissioning and implementation

Technical Data

Technical data

| Electrode force (in N) | 6,500 |

| MF transformer (in kVA) | 140 |

| Fitting (in mm) | 700 |