Rotary indexing systems

NIMAK roterande indexeringsanläggningar – många processer på ett litet utrymme

En roterande indexeringsanläggning är ofta den metod som väljs när det utrymme som finns tillgängligt för en automatiserad lösning är kraftigt begränsat i fabriken. Det beror på att många svets-, bocknings-, markerings- och limningsprocesser kan köras i roterande bordsystem parallellt i trånga utrymmen. Vi utvecklar och tillverkar roterande indexeringsmaskiner med två till åtta stationer för dig – om du vill, även med uppströms och nedströms tillverkningsstationer som sammankopplade anläggningar. Oberoende av betongarrangemanget i din roterande indexeringsanläggning kan du alltid använda dem för att förkorta tillverkningstiderna. Inte minst tack vare en mycket hög anläggningstillgänglighet och de mest stabila processerna. Det beror på att NIMAK-anläggningar står för pålitlig kvalitet och högsta prestanda.

NIMAK rotary indexing plants – many processes in a small space

A rotary indexing plant is often the method of choice when the space available for an automated solution is severely limited in the factory. That is because many welding and even punching, bending, marking and gluing processes can be run in rotary table systems in parallel in tight spaces. We develop and fabricate rotary indexing machines with two to eight stations for you – if you want, even with upstream and downstream manufacturing stations as interlinked plants. Independent of the concrete arrangement of your rotary indexing plant, you can always use them to shorten manufacturing times. Not least thanks to a very high plant availability and the most stable processes. That is because NIMAK plants stand for reliable quality and the highest performance.

Professional standards and individual solutions for your rotary indexing table plant

Off the shelf solutions are not something we believe in. Ultimately, every automation challenge is different. That is why we do not have any prefabricated rotary indexing table plants in our product catalog. Instead we rely on using synergies and proven standards whenever possible. In reality it looks like this: If you approach us with a concrete automation requirement that can best be handled by a rotary indexing machine, at the start of the design phase we will consider very exactly if we could possibly use one or more of the standard ones that we have already developed. If that is in fact the case, time and cost advantages are associated, from which you benefit. That is because we use our existing solutions as the basis and correspondingly supplement them or adapt them to match your needs. If there aren’t already any approaches that can help us along, we develop and design a completely new one for you. In any case, at the end you will be able to work with a fully-automated, high-performance rotary indexing table plant.

Everything from one source: Development, design, manufacturing and service

We develop, design and fabricate not only individual rotary indexing machines but we also take care of the installation and commissioning onsite together with the instruction or training of your employees. That means you obtain all services from one, single source at the highest level of quality. Our outstanding qualified developers, design engineers, technicians and fitters who work together with you hand in hand ensure that. During all phases of development, manufacturing and commissioning we also keep in close contact with your experts. We use this method to ensure that we understand all details in depth, develop tailor-made solutions and can quickly react to any change or adaptation requirements.

Pamphlet / Broschyr

Video

Challange

A prime example from real life:

Keep the level of automation flexible with a four-station rotary indexing plant

Our customer welds sintered metals with high carbon content. He wants a welding plant that he can use variably – sometimes as a manual workstation, sometimes fully automated for pilot and large-scale manufacturing.

Solution

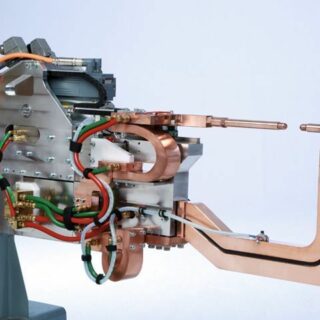

Increase or reduce the level of automation with the press of a button

We developed four-station rotary indexing plants in which the automation elements can be switched in or out as needed. A fast, precise handling robot is used here. Indexable tools that can be changed in the shortest possible time make operation simple.

Results

Higher quality, shorter process times, more productivity

- Outstanding welding results: Capacitor discharge with the optimum follow-up unit

- Optimum production sequence: Automated supply and removal of sinter and welding parts

- Higher productivity: Cycle times of less than five seconds

- Guaranteed quality: Integrated PQS quality monitoring module

- User-friendly and time-saving: Robots with camera system for component detection

- Everything from one, single source: from the basic concept to commissioning and implementation

Technical Data

| Electrode force (in daN) | 2,000 |

| KES power (in Ws) | 16,000 |

| KE transformer (in kVA) | 160 |