Manual gluing application systems

Doseringsenheten för manuell användning: NIMAK:s manuella limningsanläggning

Som en limnings- och doseringsenhet för manuell användning övertygar NIMAK:s manuella limningsanläggning med sin robusta design och stora användarvänlighet. De manuella limutrustning och materialslangstyrningen är placerade vertikalt för ergonomisk användning. Den perfekt formade manuella limutrustning är lätt för användaren att kontrollera. Med NIMAK manuell limningsanläggning kan du applicera alla lim som är vanliga i bilindustrin samt många ytterligare lim, tätningsmedel och isolerande material med hög precision. Kontakta oss. Vi skulle gärna konsultera dig individuellt om dina manuella limningssystem från NIMAK.

Mer än bara en manuell doseringsenhet: Din färdiga kompakta anläggning

Vårt limnings- och applikationssystem består av fem huvudkomponenter:

- Manuell doseringsenhet

- Tryckkolvspump

- Pneumatisk pumpstyrning

- Värmekontroll

- Pumpkolonn

Vi tillhandahåller den ergonomiska manuella limpistolen i uppvärmda och ouppvärmda versioner. Oavsett vilken version du bestämmer dig för, är båda utformade så att den manuella spärrspaken enkelt kan aktiveras även med handskar vid applicering av lim. Beroende på uppgiften kan olika nålstorlekar användas på applikationshuvudet. Till våra manuella limningsanläggningsregulatorer förlitar vi oss uteslutande på Siemens standardkomponenter som fungerar tillförlitligt, och som snabbt och enkelt kan bytas ut under eventuellt reparationsarbete.

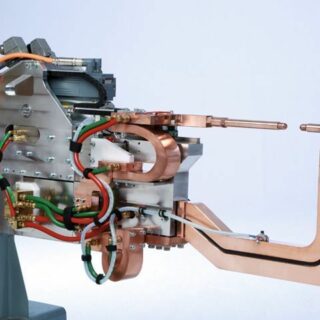

The glue dosing unit for manual use: the NIMAK manual gluing plant

As a gluing and dosing unit for manual use, the NIMAK manual gluing plant convinces with its robust design and great user friendliness. The manual glue guns and material hose guidance are positioned vertically for ergonomic usage. The perfectly shaped manual gluing gun is easy for the user to control. With the NIMAK manual gluing plant you can apply all the glues that are common in the automobile industry as well as many additional glues, sealants and insulating materials with high precision. Get in touch with us. We would be glad to individually consult you on your manual gluing systems from NIMAK.

More than just a glue manual-dosing unit: Your ready-to-use compact plant

Our gluing and application system comprises five main components:

- Manual gluing gun

- Scoop piston pump

- Pneumatic pump control

- Heating control

- Pump column

We provide the ergonomic manual gluing gun in heated and unheated versions. Regardless of which version you decide on – both are designed so that the manual ratchet lever can be easily actuated even with gloves when applying glue. Depending on the task, various needle sizes can be used on the application head. For our manual gluing plant controllers we rely exclusively on Siemens standard components that work reliably and that can be quickly and simply replaced during possible repair work.

Components

Your complete application system for manual gluing work

Manual gluing gun

- Optionally heated or unheated

- Robust design

- Simple operation (compatible with gloves)

- Various needle sizes can be used

Scoop piston pump

- Delivery rate: 220 ccm/double stroke

- Max. operating pressure: 350 bar

- Input pressure: 6 bar

Pump columns and pneumatic pump control

- For operation of the pump column functions: lift, lower, vent drum, etc.

- For operation of the pump functions: switch on and off, vent, etc.

- Integrated safety mechanism in case of incorrect operation

Heating control

- 5 heating circuits

- Temperature input through display

- Harting connector plug

Advantages

Benefits in an overview:

Robust and simple to use

The compact manual gluing plant is designed sturdy and simple to operate. Thanks to the ergonomic handle and the vertical routing, employees can even apply glue with great precision while wearing gloves.

Durable plant

The heated system prevents adhesion within the unit, which contributes to the NIMAK manual gluing plant being able to work reliably for a long time.

Low maintenance expenditures, simple spare-part procurement

The robust-manufactured and simply setup manual gluing plant requires little maintenance. Thanks to the use of SIEMENS standard components in the controller section, possibly needed spare parts can always be obtained anywhere.

Areas of Application

The NIMAK manual gluing gun is used in both trade companies as well in industry. Namely always when automated gluing systems do not pay off. Many of our customers work with a manual dosing unit in the following sectors:

- Vehicle development/pilot shops

- Prototype construction/pilot series centers

- Start-up factories

- Rework stations

- CKD production