MultiframeGun, Svetstång

multiframeGUN

En platta och fem komponenter skapar grunden för mer än 1 000 000 versioner av Nimaks multiframeGUN. Det gör den till en all-round-svets bland robotsvetsar. Du berättar helt enkelt för oss i vilka produktionsprocesser du vill använda multiframeGUN, och baserat på vårat modulära modulsystem, kan vi designa och bygga rätt C- eller X-tång för dig – i högsta kvalitet och till ett attraktivt pris. På så sätt drar du direkt nytta av vår mångåriga designerfarenhet inom motståndssvets. Det är trots allt det som skapar grunden för vårt kraftfulla multiframeGUN modulära modulsystem. Vad händer om du behöver en enskild svetstång istället för en hel svetsanläggning? Det kan vi lösa också!

Modulär allroundmaskin som tål höga dynamiska belastningar: multiframeGUN

Certifierad för högdynamiska robotar

Robotar som arbetar allt snabbare ställer stora krav på svetstångafäste. MultiframeGUN har visat sig kunna hantera dem perfekt. Den har trots allt certifierats som hittills den enda svetstången på marknaden för drift på högdynamiska robotar. För dig betyder det: Med multiframeGUN har du en utmärkt position för nuvarande och framtida krav.

- Description

- Pamphlet / Broschyr

- Advantages

- Technical Data

- Complementary products

- Video MultiframeGun

multiframeGUN

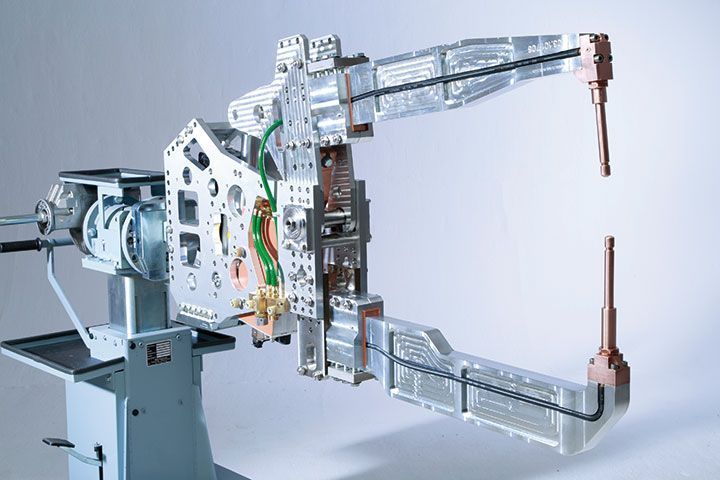

One plate and five modules create the basis for more than 1,000,000 version variants of the multiframeGUN. That makes it an absolute all-rounder among robot welding guns. You simply tell us the production processes you want to use the multiframeGUN in, and based on our multiframe modular building kit, within the shortest possible time we will design the right C- or X-gun for you – in the highest quality and at an attractive price. That way, you profit immediately from our many years of design experience in the automobile industry. After all, that is what creates the basis for our powerful multiframeGUN modular component system. And what if you need an individual gun instead of a complete welding plant? We would be glad to realize that for you too. Let’s talk about it.

Modular all-rounder that withstands highly dynamic loads: the multiframeGUN

Certified for highly dynamic robots

Robots that work ever-faster put great demands on welding gun retainer systems. The multiframeGUN is proven to be able to perfectly cope with them. After all, it has been certified as the only gun on the market up to now for operation on highly dynamic robots. For you that means: With the multiframeGUN you are in an excellent position for current and future requirements.

High-performance modules

The multifunction plate

It bears the modules for all multiframeGUNs:

- 20 mm rolled plate material without plane-parallel processing

- Only one mounting since processing only from one side

- No thread, no stepped holes

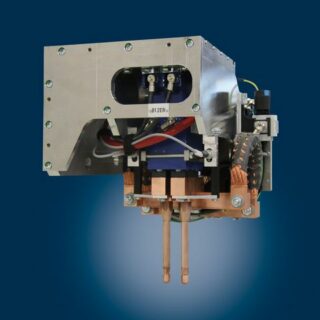

NIMAK gun drive

- Power up to 20,000 N/stroke 0 to 162 mm (guaranteed: 15,000,000 strokes) /efficiency > 95%

- Completely enclosed housing

- Maintenance-free through oil bath lubrication

- A ball-roller spindle drive for X- and C-guns

- Optional motors from any manufacturer

Standardized NIMAK lightweight MF transformer

- MF-technology 1,000 Hz

- 6.5 kA continuous current

- Cooling water supply 6l/min

- Rotation of poles through symmetrical setup

- 130 kVA at 20 % duty ratio

- Weight 15 kg

Flexible arm attachment

- E-arm cross-section optionally 60 mm or 90 x 40 to 150 x 40 mm in diameter

- Base body window: Width 300 – 500 mm (X-gun) or 200-350 mm (C-gun), – grid 50 mm

Guide C-gun

- Height and side adjustable ball-rail system

- Force-locked to side panel through adapter bolts

Motion link with bearing

- Stable chain roller bearing

- Steel bushings against deflecting on the axis

- Undivided side panels for optimum force flux

- Force-locked against axial shifting

Pamphlet / Broschyr

Advantages

Extremely slim design: perfect even for difficult to access welding work

The transformer, current bands and servodrive are completely integrated into the gun body which means that no bothersome parts stick out.

Greatest flexibility: Six interfaces for the link to the robot

Place the multiframeGUN wherever you want – top, bottom, rear or laterally on the robot. Everything is possible – and without separate consoles

Best price: made affordable with just a few, simple parts

Thanks to the limited number of parts we are able to produce your multiframeGUN cost-effectively and even the costs for maintenance and spare parts are low.

Highest efficiency: reduced gun weight makes the use of smaller robots possible

The comparatively light guns can be moved quickly and lengthen the operating lives of the robots and guns.

Technical Data

| Brief overview | |

|---|---|

| Rated power | 130 kVA/20 % duty ratio |

| Max. E-force (in kN) | 8 with 800 mm projection X-gun |

| Arm distance C-gun (in mm) | 150 – 375 mm |

| Arm distance X-gun (in mm) | 200 – 500 mm |

| Weight C-gun (in kg) | from 90 |

| Weight X-gun (in kg) | from 113 |

Complementary products

topCONTROL gun controller

topCONTROL makes your robot gun intelligent. With this motor controller that can be easily attached to the gun you can define all relevant functions in detail and, for instance, precisely set the force profile. That means that topCONTROL exceeds the performance of many robot controllers and not only concerning the number of software programmable features but also with consideration of exactness and precision. Even highly-demanding welding jobs can be reliably and exactly performed. Another topCONTROL plus: The controller can even be retrofit onto extant guns and integrated in all makes of existing plants to effectively increase their capability.

gunTEST gun test center

With gunTEST during routine repair work you can always exactly check whether your robot welding guns are operating with full power after possible repairs and maintenance work right onsite in your production plants. Our test center, which is specifically aligned to the gun standard you use, finds that out within 15 minutes, helping you prevent downtimes.