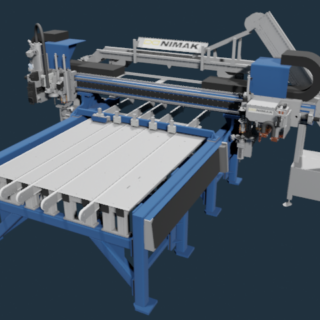

Sömsvetsutrustning, Roller seam welding machine

SV

Det viktigaste med sömsvets är att svetssömmen är ogenomtränglig. Detta är precis vad Nimak högkvalitativa sömsvetsmaskiner garanterar.

Nimaks sömsvetsutrustning är byggda enligt era specifikationer och önskemål. Vi testar olika metoder på testmaterial, som ni förser oss med, i Nimaks svetslabb. Med testerna kan vi säkerställa att vi uppnår de svetssömmar ni vill ha.

EN

Impermeable seams guaranteed; with roller-seam welding

The most important thing during roller-seam welding is that the seam is impermeable. That is exactly what our high-performance machines guarantee. Nimak always produce at the highest level of quality and according to your requirements.

The exact appearance of your machine depends on your individual needs. We will gladly also take concrete specifications, for instance regarding pneumatics, controller or color, into account. After all, your requirements for roller-seam welding are what drives us.

- Individually configurable with the modular system

- Optionally alternating current technology, in medium-frequency design

- With transverse or longitudinal weld tracking

- One or two roller drive

You specify the main parameters: Should it be a machine in transverse or longitudinal weld tracking? Should both rollers be driven or only one? We would be glad to assist you with the decisions and will make concrete recommendations based on your individual welding requirements. Based on specimens that you provide us, our experts in the welding lab will perform analyses, test various methods, and create prototypes that are likewise put through the paces. At the end of the process, an individually designed and fabricated roller-seam welding machine that meets your roller-seam welding requirements is manufactured.

Typical applications

Whenever impermeable welding seams are demanded, our roller-seam welding machines perform reliable, continuous work. For example

In the automotive supplier industry, for instance for the production of shock absorbers and also for the manufacture of:

- Tanks

- Fire extinguishers

- Drums, etc.

Technical Data

- Water cooled

- Arm-clearance hydraulically adjustable

- Reach available in various lengths; special sizes on request

- Controllable electrode force

- With compressed-air maintenance unit

- Separately adjustable cooling-water circuits with flow rate and temperature indicator

- Throttle valve for bounce-free electrode placement

Overview of Types

Welding machines in alternating current or medium-frequency technology

| Type | NMP 7 | NMP 12 |

|---|---|---|

| Nominal output at 50 % duty ratio (in kVA) | 80 – 160 | 160 – 250 |

| Max. welding current (in kA) | 29.6 | 45.6 |

| Electrode force (in daN) | 145 – 860 | 200 – 1,200 |

| Electrode stroke (in mm) | 100 | 100 |

| Projection (in mm) | 550 – 750 | 550 – 750 |

Pamphlet / Broschyr

Roller-seam welding machine pamphlet/ Sömsvetsmaskin broschyr