SmartDosing

SV

Nimaks SmartDosing-system är en lättare, mer kompakt och en ekonomisk lösning för lim- och tätningsapplicering.

Med den lätta vikten på 5 kg och den kompakta designen, är Nimaks SmartDosing inte bara lätthanterlig för processrobotar, utan även för operatörerna.

Denna appliceringsutrustning innehåller färre delar, vilket gör att färre reservdelar behöver vara lagerställda samt att det är smidigt att byta dessa vid behov.

Detta gör också att rengöring av utrustningen blir lättare jämfört med standardenheterna.

Trots allt detta sviker inte SmartDosing i kvalité.

EN

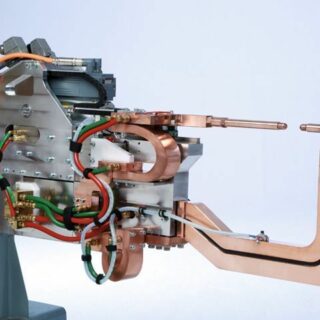

Adhesive dosing system without doser

The new system developed by NIMAK for 1-component adhesives does not require a metering unit. The core of this innovation is a drum pump concept that has been implemented for the first time and is completely motorized. Please contact us. We will be happy to advise you individually about your smartDOSING adhesive application system from NIMAK.

Ideal for most applications: Save a lot of money with smartDOSING!

Our gluing and application system essentially consists of only the two main components

- Application head

- Pump stand

In the Plus version of smartDOSING, the opening angle of the application nozzle can also be adjusted on the application head. This allows different seam widths to be applied. This is particularly important if the adhesive seam is not only straight, but also curves.

Thanks to the slim and space-saving application head, smartDOSING is particularly suitable for body shop applications, where poor accessibility to components often hinders the application of adhesives.

The application head weighs no more than 5 kg and is therefore significantly lighter, enabling it to be used on small and inexpensive handling robots. Other advantages include simpler configuration, fewer interfaces and, thanks to the servo motor, high precision during dosing.

Environmentally friendly electrical energy is used instead of expensive compressed air

- 30 % investment savings potential compared to classic dosing

- Reduce also your CO² balance with smartDOSING

Components

Application head

- One size fits all

- Max. weight: 5 kg

- Fully electric

- Integrated pressure sensor to control the material pressure in the system

- Reduced number of parts

Electic pump stand

- Simple technology with robust construction

- A guided stroke on the rear side that moves the follower piston plate

- One electrically driven pump (heated / unheated)

- Integrated pressure sensor

- Innovative follower plate design to reduce waste

- One frame design for 20l, 50l and 200l drums (600mm wide)

Optional

- Laser seam monitoring

- Online seam monitoring

- Downstream camera monitoring

Advantages

Benefits in an overview:

- Savings on investments in new plant technology

- Savings in spare parts stocking

- Savings in the operation of running plants

- Constant quality of the application at a good level

- Constant and stable process over the entire life of the plant

- Less weight

- Less maintenance

- Less fixture interference