The EXPERT-TÜNKERS construction principle

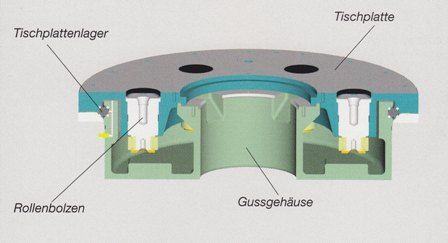

- Table plate and housing accommodate the bearing

All conventional needle bearings or crossed roller bearings severely narrow the constructive possibilities as to the realisation of simple and therefore robust solutions.

In the process, tables must be equipped with additional seals or column-like centre structures to support the axial loads.

With EXPERT-TÜNKERS rotary tables however, the table and the housing directly

serve the accommodation of the bearing. Next to an extremely space-saving design, the following advantages are created:

– solid, level table encompassing the ball bearing; ideal structural base for fixtures,

no interfering edges;

– safe protection of the mechanisms underneath against weld splatter, splashes of water etc. without additional seals etc.;

– very simple construction as only one external bearing is required, whereas other

types of construction rely on up to three bearings (axial and radial), which have to be adjusted to each other;

– high bearing loads can be realised, as the bearing is optimally installed at the

outer perimeter of the table;

– easy maintenance, bearing can be readjusted without removal of the table.

- Wider opening in the centre column

Due to the bearing being externally located, the centre area of the table housing and the rotary plate can be freely designed and it allows for a large central opening for media supply lines.

Tischplatte – Table plate

Gussgehäuse – Cast housing

Rollenbolzen – Cam follower

Tischplattenlager – Table plate bearing

- Easy disassembly of cam followers

Overstressing of rotary tables, e.g. through crash or operating errors can cause

defects to driving cams. The EXPERT-TÜNKERS construction allows for easy replacing of cam actuators from the top, even as to jammed tables.

- Low-backlash in working position due to the cam drive principle

With indexing tables the plate is driven via two cam actuators.

In zero position they move to a broadened cam profile resting in this position and therefore provide for a locked working position virtually free of play.

- SMARTTURN: Rotary pulse generator instead of “skewer“

The new generation of rotary tables is optionally supplied with an inductive rotary pulse generator and the stand-alone SmartTurn control,

which replaces complex mechanical barring gears and controls the tables fully automatic.

Advantages:– Self-teaching system

– Easy initial operation due to the first movement cycle

– No readjustment required

– Integrated monitoring of the brake path, including brake wear, with alarm signal “Reline“ and emergency shutdown

Overview of aspects in favour of EXPERT-TÜNKERS rotary tables

Einfaches Austauschen…

Easy replacement and inspection

of cam actuators from the

top – without disassembly of the

customers’ fixtures

Einteilige geschlossene…

Solid closed and

level table plate with

large assembly area

Größere Öffnung…

Wider opening with centre

column for media supply

Ein Lager am…

One bearing located

at the outer perimeter

Drehgeber Smartturn…

Rotary pulse generator SmartTurn

instead of “skewer“

Spielarm in der…

Low-backlash fit in

working position due to

cylindrical cam profile

principle

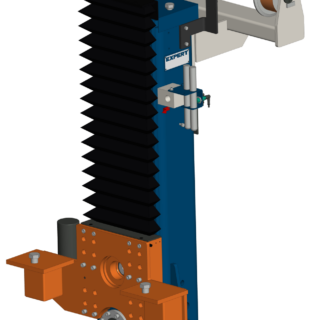

Flexible rotary tables and trunnion drives of the EDH series

are drive modules for the realisation of flexible motion operations based on the use of freely

programmable servo motors. Contrary to the standard rotary table, the cycle of motions is

not defined by the form of the index cam, but the movement profile of the servo motor.

For this reason, output angle and acceleration can be freely selected and specifically adjusted to the relevant load.

The approved EXPERT- TÜNKERS mechanical system including cam technology,

bearing and robust housing construction, provides for the same degree of precision as with conventional drives.

Designed for flexible use, rotary tables of this series are particularly suitable for driving

operations in which the sequence of motion must be permanently changed during the production process,

for instance due to new loads, new positions/end positions or directions of movement.

A typical example is the manufacture of different vehicles in one production line which necessitates flexible retooling in the production cycle.

One particular advantage of the flexible series is the extremely flat design facilitating space-saving installation and therefore ergonomic construction of fixture systems.

Specific advantages

- More torque due to the new multiple cam follower principle

- As to the EDX series, at least two cam followers are always engaged for power transmission from the drive cam to the rotary table

- Forces generated in the event of an emergency stop are distributed over several cam followers

- Considerably higher torques can be transmitted on the basis of the same dimensions

Operational principle

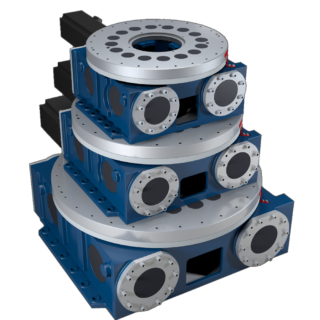

Rotary tables and trunnion drives with fixed steps of the EDX series

are precision index drives of very compact dimensions,

with fixed divisions and maximum torque for rotating movements and dynamic indexing of loads of up to 20 tons with standard cycle times of 2 – 6 seconds.

They are driven via energy-saving three-phase a.c. motors, the drive movement of which is converted into an indexed movement of the rotary table via a positive cylindrical cam profile.

Typical applications for EXPERT-TÜNKERS rotary tables are, e.g. tool changing operations in body-in-white welding lines,

the channelling in and out of workpiece carriers or rotary tables for operation sequences / manufacturing processes,

in particular with a view to serial production. EXPERT rotary drives are suitable for horizontal and vertical operation, for instance, in the form of trunnion drives.

Specific advantages

- More torque due to the new multiple cam follower principle.

- As to the EDX series, at least two cam followers are always engaged for power transmission from the drive roller to the rotary table during acceleration and deceleration.

- Forces generated in the event of an emergency stop are distributed over several cam actuators.

- Considerably higher torques can be generated on the basis of the same dimensions.

Funktionsprinzip – Operational principle

verriegelter Rastwinkel – Locked resting angle

Tischplatte – Table plate

Antriebswalze – Drive cam

Rollenbolzen – Cam followers

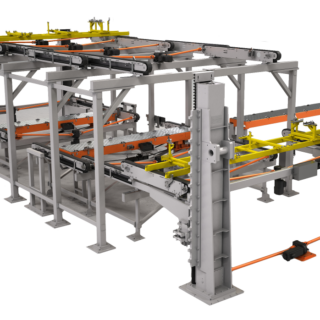

Heavy-duty rotary tables

Based on the approved construction principle of EXPERT-TÜNKERS standard rotary tables,

the heavy-duty tables reach dimensions of diameters of up to 20 metres, with payloads of up to 150 tons.

As a rule, these are specific special constructions adjusted to customer requirements.

Typical ranges of application of heavy-duty rotary tables are foundries,

the manufacture of interior products, the glass industry and the construction of large-size gears and engines.

Due to the size, the housing and table plate are constructed in segments.

Specific advantages

- Robust cam technology for high load cycles

- Tool carrier and table plate as integrated solution, providing for an extremely low installation height

- Basic construction individually adjustable to customer requirements

- Central bearings and outer support through heavy-duty rollers

- Available with fixed and flexible indexing increments (servo drive)

Rotary table with wide central opening (e.g. diameter of 1,700 mm) for installation of an additional robot in the centre.

Flexible processing of 3, 4, or 6 work steps = car body models.

Application example

Flexible ring table EDH 3250

| Type | Outer diameter

table plate (A) (mm) |

Inner diameter

table plate (I) (mm) |

Height (H) (mm) | Max. output moment (Nm) |

| EDH 2250 | 2,000 | 1,300 | 400 | 30,000 |

| EDH 2750 | 2,500 | 1,500 | 500 | 60,000 |

| EDH 3250 | 3,000 | 1,700 | 600 | 100,000 |

Technical data

Application examples

EXPERT-TÜNKERS heavy-duty rotary tables are calculated and constructed according to customer specifications.

Please feel free to forward your technical data for designing.

Please contact us with reference to CAD data or if you should have any further queries.

SmartTurn – The contemporary rotary table control

Simple

- Robust

- Intelligent

- Plug and Play

- Universal (one fits all)

Old solution:

Fast rotary tables with fixed steps used to be controlled via a number of cam switches

- Bulky

- Liable to wear

The overriding system PLC queried the switch status and controlled the motor via contactor (or frequency converter)

- Programming expense

- Cam adjustment

- Start-up expense

New solution:

- Sensor mounted to the drive shaft of the rotary table

- Control on the table housing (or at an easily accessible place nearby)

Mount, connect, operate…

SmartTurn components control the movement from position to position

Sensor – Mounted to drive shaft (wie Spieß) Control – Mounted to table housing or easily accessible places

References

- Benteler

- Claas

- Daimler

- Ford

- Magna

- Porsche

- PSA

- Skoda

- VW