Single-sided resistance spot welding

Svetsa tillförlitligt där det blir trångt: Robotsvetstänger för ensidig punktsvetsning

Det finns produktionsprocesser där, på grund av design eller konstruktionen, där lederna som behöver svetsas endast kan bearbetas från ena sidan av materialet. Av den enkla anledningen att det inte finns tillräckligt med utrymme för att placera motelektroden på baksidan. Så är fallet inom vissa sektorer av bil- och bussproduktion, men ofta också i kontrollskåp och tank-konstruktion. Med våra robotsvetstänger för enkelsidig motståndssvetsning kan ni enkelt och tillförlitligt lösa denna speciella svetsutmaning. Oavsett om komponenten ska svetsas ihop på ett tillförlitligt sätt eller svetspunkterna används under limning för fixering.

Låt oss veta vilken komplex utmaning ni står inför när det gäller enkelsidig svetsning – vi kommer att kontrollera svetsbarheten och designen, och tillverka den perfekta robotsvetstången för er. Och tack vare en flexibel design, på kortast möjliga tid.

Weld reliably wherever things get tight: Robot welding guns for single-sided resistance spot welding

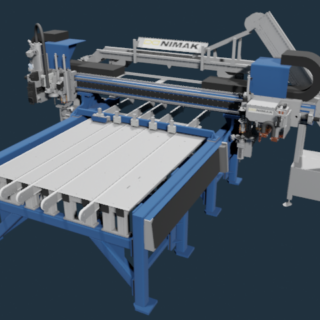

There are production processes where, due to the design or construction, the joints that need to be welded can only be processed from one side of the material. For the simple reason that there is not enough space to place the counter-electrode on the rear. That is the case in some sectors of automobile and motor bus production, but often also in control cabinet and tank construction. With our robot welding guns for single-sided resistance spot welding you can easily and reliably solve this special welding challenge. And namely independent of whether the component should be reliably welded together or the welding points are used during gluing for fixating.

Let us know which complex challenge you are facing in the area of single-sided welding – we will check the weldability and design and fabricate the ideal robot welding gun for you. And, thanks to a flexible design, in the shortest-possible time.

Technology

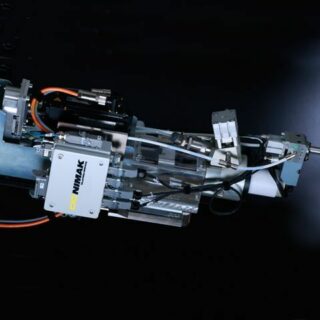

Gentle power for tricky joining jobs

The robot welding guns for single-sided resistance spot welding from NIMAK work with the latest medium-frequency transformers, a controller with adaptive welding current control and finely adjustable welding cylinders for gentle power. What’s important here is just the right amount to reliably join the materials without deforming them or leaving marks on the visible side. Our systems perfectly master this job.

Variants

Two variants for all requirements

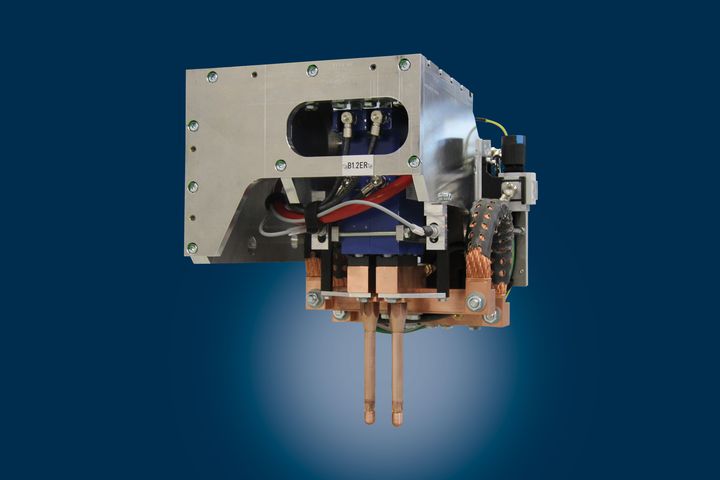

Spot welder with one electrode and one welding point

To let the current flow, a ground cable is attached to the rear sheet. Alternatively, the spot welder itself can be equipped with another flat ground electrode for the current return flow.

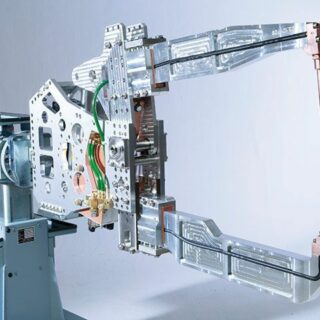

Duplex spot welder with two electrodes

The duplex spot welder works with two electrodes that simultaneously press onto the sheet from one side. The result is that two spot welds are made in one work step.

Advantages

Benefits in an overview:

Welding from only one side: join reliably without a counter-electrode

The transformer, controller and finely adjustable welding cylinder create a gentle force that reliably creates connections and goes easy on materials.

No slipping during gluing: Spot welds that last

Fixate single-sided weld points on the joining parts while the glue is hardening.

Fits your requirements: flexible design

We construct the robot welding guns for single-sided resistance spot welding for you so that they exactly fit your requirements.

Areas of applications

Typical applications

Our robot welding guns for single-sided resistance spot welding are used in applications whenever it is not possible to work with a counter electrode due to the design or construction. For instance in these sectors:

- Car and motor bus production: Body side panels, doors and flaps

- Switchgear construction: large doors

- Tank construction Welding on brackets and similar

- Linings made of corrosion resistant steel

- Railway vehicle manufacturing