Spot welding machine

Exakt och kraftfull: Punktsvetsning tillverkad av NIMAK

Vi tillverkar din punktsvetsmaskin skräddarsydd exakt efter dina behov samtidigt som vi faller tillbaka på ett kraftfullt modulsystem vars element för punktsvetsning vi designar och tillverkar själva. Dina individuella specifikationer – samtidigt tar vi gärna hänsyn till dina specifikationer, till exempel pneumatik, controller eller färg. För att uppnå detta bidrar vi med vårt sunda kompetensdjup från mer än 50 års erfarenhet. Och vi garanterar högsta kvalitet, kortare leveranstider och toppvillkor. Från en grundläggande till en premiummodell för tillverkning av industriserier – vi kommer att implementera den maskin som bäst passar dina behov samtidigt som vi erbjuder dig en omfattande tillbehörslinje. Om du vill kan du skaffa många av våra svetsmaskiner antingen som bordsskiva eller golvmaskin.

Individuellt konfigurerbar med modulsystemet

Tillval i växelströmsteknik, i medelfrekvensversionen eller som kondensatorurladdningsmaskin

Valfritt med pneumatisk eller servomotordriven enhet eller med magnetiskDRIVE

Som bords- eller golvversion

För verkstäder och rymdbesparande C-modul för svetsceller

Precise and powerful: Spot welding made by NIMAK

We manufacture your spot welding machine tailored exactly to your requirements while falling back on a powerful modular system whose elements for spot welding we design and fabricate ourselves. Your individual specifications – at the same time we will gladly take your specifications, for instance the pneumatics, controller or color, into consideration. To accomplish that we contribute our sound depth of expertise from more than 50 years of experience. And we guarantee the highest quality, shorter delivery times and top terms. From a basic to a premium model for industrial series manufacturing – we will implement the machine that best fits your needs while offering you a wide-ranging accessory line. If you want, you can obtain many of our welding machines either as a table-top or a floor machine.

- Individually configurable with the modular system

- Optionally in alternating current technology, in the medium frequency version or as a capacitor discharge machine

- Optionally with pneumatic or servomotor-driven drive or with magneticDRIVE

- As a table-top or floor version

- For workshops and industry space-saving C-module for welding cells

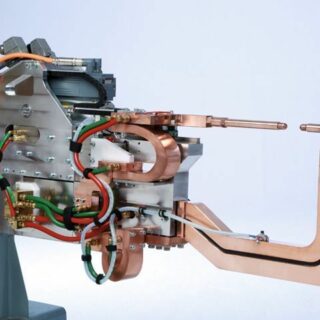

Resistance spot welding: we manufacture all the parts ourselves

From the transformer to the controller – we develop, design and produce the components of the welding-machine modular component system ourselves, which ensures that each individual component satisfies the highest demands on quality and performance. Along with the individual components of the spot welding machine itself, we design and fabricate numerous special welding tools for you that you can flexibly combine with our standard welding machines. The result is individual total solutions at an attractive price for each spot welding process. On top of that, for use in automated cells we developed an in-house welding module that, thanks to its slim design, can also be used when space is tight but is still productive: the C-module.

KES spot welding machine: maximum power with minimal connected load

Wherever only heavily restricted electrical supply lines are available or if a great deal of energy has to be achieved in a short time, our welding machines with capacitor discharge technology – abbreviated PowerKES – guarantee the perfect weld connection. The PowerKES works with high-power capacitors that are charged during the welding breaks and are then discharged for welding. The welding time is very short; the welding process itself is very energetic. It allows connecting very different materials, galvanic and hot-dip galvanized sheets, high-allow steels, grain-refined construction steel, high-strength and multiphase steels as well as steel grades with a high carbon content. Because the heat development is concentrated solely on the welding point, the surrounding material is spared. The heat-affected zone remains small. Two additional advantages of the PowerKES: Since energy only needs to be applied in the process for a very short time, the thermal stress is reduced so that the machine can be operated in part completely without water cooling. Compressed air is also not necessary in the servomotor driven PowerKES versions. From the economic aspect, that makes them additionally attractive. We also provide our PowerKES welding machines as table-top and floor versions.

For even gentler but lightning-fast spot welding technology: magneticDRIVE

Decide on a spot welding machine with magneticDRIVE, which uses the immense power and speed of the latest microprocessor-controlled electromagnets. Specifically when using capacitor discharge welding machines with their extremely short welding times, a force-locked follow-up is indispensable for low-spatter welding and the best welding results. In contrast to conventional follow-up units, magneticDRIVE provides you the full flexibility and dynamics of an electromagnet. At the same time, the required spot-welding electrode force, adapted force profile and the follow-up characteristics can be perfectly adapted to your requirements during spot welding through the appropriate control engineering. Find our more right now!

Pamphlet / Broschyr

Advantages

Benefits in an overview:

Individually configurable

We will configure the perfect device for your welding challenge. To accomplish that our technicians in the welding lab step into action for you: they perform trials in the welding lab on the materials you have supplied, create and test the welding samples and determine the main welding parameters. That information is used to create your plant quickly and cost-effectively.Robust and tough

High-grade components, excellent craftsmanship and the massive, torsion-free basic body of our spot welding machines guarantee their long durability and high-quality weld connections. The are often used for many decades and permanently work with absolutely reliability.

Shorter delivery times, good price-performance ratio

A comprehensive modular system, the production of individual components in our own factory and highly-qualified employees with many years of experience ensure that we can supply high-quality resistance spot welding equipment quickly at attractive prices.

Meet the safety regulations

All spot welding machines that leave our factory meet the legal safety regulations and comply with the high requirements of Performance Level D.

Areas of Application

Typical applications

Whether trade or industry – spot welding machines create reliable welding connections everywhere,

and in these industries also:

- Automobile production

- Transportation means manufacturing

- Household goods production

- Metalworking

- Ventilation and air-conditioning technology

Facts and Figures

At a glance: important technical details

Floor spot welding machines with alternating current or medium-frequency technology:

- Water cooled

- Separately adjustable cooling-water circuits with flow rate and temperature indicator (models: PMP6, PMP11)

- Reach within the modular system freely selectable; special versions on request

- Electrode force controllable (step switch)

- With compressed-air maintenance unit and pressure gage

- Pneumatically actuated tandem cylinder with outstanding follow-up characteristics, optionally with servomotor drive or magneticDRIVE.

- Throttle valve for bounce-free electrode placement

Table-top spot welding machines with alternating current or medium-frequency technology:

- Water cooled

- Single stroke cylinder

- With attached compressed-air maintenance unit

- One cylinder chamber can be switched off

- With machine table and lateral storage shelves

- Foot-operated switch

Floor and table-top welding machines with capacitor discharge technology

- Welding head driven by a servomotor, alternatively also pneumatic, hydraulic or with magneticDRIVE

- Fuse protection 16–63 A

- Capacitor charge time 0.3–2.0 seconds

- Extremely fast increase in current

- Minimum heat development, that means

… low electrode wear

… no annealing of the materials

… operation without cooling system - Clearance-free precision guide

- Mechanically decoupled follow-up unit; alternative: magneticDRIVE

- Galvanically silver-plated secondary circuit

- Torsion-resistant steel structure in C-design; alternative: portal structure

- Control console with industrial PC and user-friendly menu guide

Technical Data

Choose between these high-performance spot welding machines

Welding machines in alternating current or medium-frequency technology

| Floor units | Table-top units | |||||

|---|---|---|---|---|---|---|

| Type | PMP 2-1 | PMP 5-1 | PMP 6 | PMP 11 | TPMP 2 | TPMP 5 |

| Nominal output at 50% duty ratio (in kVA) | 15-35 | 60 | 80-160 | 80-250 | 8-14 | 36 |

| Max. welding current (in kA) | 10-15 | 22 | up to 52.8 | Up to 74 | 8.2-11.2 | 26 |

| Electrode force (in daN) | 200 | 300-500 | 140-900 | 90-1,600 | 35-210 | 40-550 |

| Electrode stroke (in mm) | 6-50 | 60 | 100 | 100 | 25 | 75 |

| Projection (in mm) | 400 | 430 | 250-1,050 | 200-1,050 | 150 | 295 (protruding 200 + 95 mm) |

Welding machine with capacitor discharge technology

| Type | TableKES | PowerKES 5 | PowerKES 10 | PowerKES 20 | PowerKES 100 | PowerKES 200 |

|---|---|---|---|---|---|---|

| Max. welding current (in kA) | up to 700 | up to 700 | up to 700 | up to 700 | up to 700 | up to 700 |

| Electrode force (in daN) | up to 200 | up to 200 | up to 200 | up to 200 | up to 200 | up to 200 |

| Welding power (in WS) | max. 8,000 | max. 16,000 | max. 12,000 | max. 24,000 | max. 42,000 | max. 140,000 |

| Electrode forces (in kN) | 5.5 | 16 | 20 | 30 | 100 | 200 |